In today’s fast-paced and competitive business world, it is crucial for companies to continuously improve their processes and operations to stay ahead of the competition. This is where value stream mapping comes in, as it is a powerful tool that can help organizations identify and eliminate waste, improve efficiency, and ultimately achieve operational excellence. In this article, we will delve into the concept of value stream mapping for process optimization, exploring how it can be used to improve operational leadership and organizational efficiency. Whether you are a business owner, manager, or process improvement specialist, understanding the principles of value stream mapping can greatly benefit your organization. So let’s dive in and discover how you can implement this powerful tool in your own company’s journey towards continuous improvement.

Welcome to our guide on using Value Stream Mapping for process optimization. As a business leader, you are constantly seeking ways to improve your organization’s efficiency and performance. In this article, we will explore the basics of Value Stream Mapping, its benefits for operational leadership, and how it can help you improve your team’s performance. By implementing this technique, you can become a more effective leader and drive success in your operations.

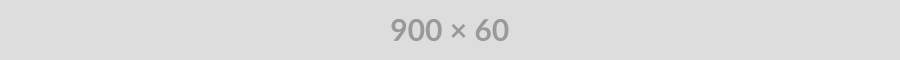

Value Stream Mapping (VSM) is a powerful tool used to identify and eliminate waste in processes. It provides a visual representation of how materials and information flow through your organization, allowing you to identify areas of improvement and optimize your processes for maximum efficiency.

One of the key benefits of VSM is its ability to help leaders make data-driven decisions. By mapping out your processes, you can easily identify bottlenecks, redundancies, and other areas that may be causing inefficiencies. This information allows you to prioritize improvement efforts and allocate resources effectively.

Another advantage of VSM is its role in promoting operational leadership. By using this tool, leaders can gain a better understanding of their team’s workflow and performance. They can then use this knowledge to foster a culture of continuous improvement and drive success in their operations.

So, how can you effectively use VSM in your organization? Here are some tips:

- Start with a clear goal: Before creating a value stream map, define the specific problem or goal you want to address. This will help you focus your efforts and ensure that your map is relevant and useful.

- Involve your team: VSM is not just a tool for leaders; it involves everyone in the organization. Make sure to involve your team in the mapping process to gain different perspectives and ensure buy-in.

- Use visuals: VSM is a visual tool, so it’s essential to use clear and easy-to-understand diagrams. This will help everyone in the organization understand the map and identify areas for improvement.

- Continuously update your map: As your processes evolve, so should your value stream map. Make sure to regularly review and update it to keep it relevant and useful.

Now, let’s look at some real-life examples of organizations that have successfully used VSM to optimize their processes:

- Toyota: The famous automaker used VSM to streamline their production processes and reduce waste. This helped them improve efficiency, reduce costs, and increase customer satisfaction.

- Amazon: The e-commerce giant used VSM to identify bottlenecks in their fulfillment centers and implement solutions to improve their delivery times. This resulted in faster and more reliable delivery services for customers.

- General Electric: The multinational conglomerate used VSM to streamline their manufacturing processes, resulting in a significant reduction in lead time and improved product quality.

In conclusion, Value Stream Mapping is a powerful tool for process optimization and operational leadership. By implementing it in your organization, you can identify and eliminate waste, make data-driven decisions, and become a more effective leader. Remember to involve your team, use visuals, and regularly update your map for the best results. With these tips and real-life examples, you now have the knowledge to use VSM effectively and drive success in your operations.

Real-Life Examples

Welcome to our guide on using Value Stream Mapping for process optimization. As a business leader, you are constantly seeking ways to improve your organization’s efficiency and performance. This article will cover everything you need to know about Value Stream Mapping, a powerful tool for identifying and eliminating waste in your processes. By implementing this technique, you can become a more effective leader and drive success in your operations. See how other organizations have successfully used this technique by analyzing real-life examples.

The Benefits for Operational Leadership

Welcome to our guide on using Value Stream Mapping for process optimization. As a business leader, you are constantly seeking ways to improve your organization’s efficiency and performance. In this section, we will focus on the benefits of Value Stream Mapping for your operational leadership skills.

Improved decision making: By utilizing Value Stream Mapping, you can gain a better understanding of your organization’s processes and identify areas that require improvement. This allows you to make more informed decisions and lead your team towards success.

Increased efficiency: Value Stream Mapping helps you identify and eliminate waste in your processes, leading to increased efficiency and productivity. As a leader, this can help you optimize your team’s performance and achieve organizational goals more effectively.

Better communication: Through Value Stream Mapping, you can visualize your processes and communicate them clearly to your team. This promotes better communication and collaboration among team members, ultimately leading to improved leadership skills.

What is Value Stream Mapping?

Value Stream Mapping (VSM) is a lean management technique used to analyze and improve the flow of materials and information through a process. It was originally developed by Toyota as part of the Toyota Production System, but has since been adopted by many other organizations as a way to identify and eliminate waste in their processes.

VSM is a visual representation of the entire process, from start to finish, including all the steps and activities involved. It helps to identify areas of improvement and potential bottlenecks in the process that can be addressed to increase efficiency and reduce costs.

This powerful tool allows leaders to see the big picture of their processes and make data-driven decisions for improvement. By understanding how value flows through a process, leaders can identify non-value added activities and eliminate them, resulting in a more streamlined and efficient process.

Overall, VSM is a crucial tool for process optimization and organizational efficiency. It provides a clear understanding of how processes work, helps to identify areas for improvement, and empowers leaders to make data-driven decisions for success.

Tips for Effective Use

Implementing Value Stream Mapping can seem like a daunting task, but with the right approach and guidance, it can be a powerful tool for improving your processes. Here are some practical tips to help you effectively use Value Stream Mapping in your organization:

1. Clearly Define Your Objectives: Before starting the mapping process, it’s important to have a clear understanding of what you want to achieve. Are you looking to reduce waste, improve efficiency, or both? Clearly defining your objectives will help guide your mapping process and ensure that you focus on the right areas.

2. Involve Your Team: Value Stream Mapping is a collaborative process and it’s important to involve your team members from different departments. This will not only provide a diverse perspective but also increase buy-in and ownership of the process.

3. Start Small: If you’re new to Value Stream Mapping, it’s best to start with smaller processes before tackling larger ones. This will give you a chance to practice and refine your skills before taking on more complex processes.

4. Be Open to Change: Value Stream Mapping is designed to identify areas for improvement, which may require changes in processes or procedures. It’s important to be open to change and willing to implement new ideas that can lead to better results.

5. Continuously Review and Improve: Value Stream Mapping is an ongoing process, not a one-time fix. It’s important to regularly review and update your maps to ensure they accurately reflect your current processes and identify new areas for improvement.

By following these tips, you can effectively use Value Stream Mapping to drive operational leadership and efficiency in your organization. Remember, it’s not just about creating a map, but using it as a guide to continuously improve and achieve your objectives.Value Stream Mapping is an invaluable tool for process optimization that can significantly improve your operational leadership skills. By identifying and eliminating waste in your processes, you can drive efficiency and performance within your organization. With the information provided in this article, you are now equipped to use this tool effectively and become a better leader in your business operations.